Contact us

13715491170

Your location:Home > News > Technical Support

Your location:Home > News > Technical SupportAnnouncer:Haosu Time:2017-03-14

(1) The spacing of the screws can be properly configured according to the thickness of the plate. The spacing is too small and too big to be good. If the spacing is too small, sometimes it will cause stress and damage because of too tight; if the spacing is too large, the PC plate will be fixed unstable. Lower pitch is recommended for this purpose:

A: the thickness is below 3.0mm and the distance is 10~20cm

B: the thickness is above 3.0mm and the distance is 20~30cm

C: If the band is fixed, the spacing is 20~30cm

Note: if the PC plate is directly fixed with self tapping screw, the greater the screw spacing is, the more difficult the plate is to be damaged by stress.

(2) The screw hole size should be considered in PC in summer and winter and different thermal expansion and contraction of the book night. Generally speaking, the screw hole diameter should be bigger than the screw at least 2~4mm, in order to reserve the expansion space

(3) The position of the screw hole is too close to the edge of the PC plate. It is easy to break the plate. In general, the screw hole is 2.5 times more than the diameter of the screw hole at the edge of the PC plate. For example, screws with a diameter of 4mm, the screw holes at least PC from the edge of the plate to be more than 1cm.

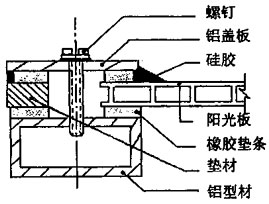

(4) The screws must not be locked too tightly, otherwise they will deform and lead to stress.

(5) The screw on the PC board is best not to use self tapping screw, otherwise it will produce stress, and the stress will increase as the thickness of the sheet increases.

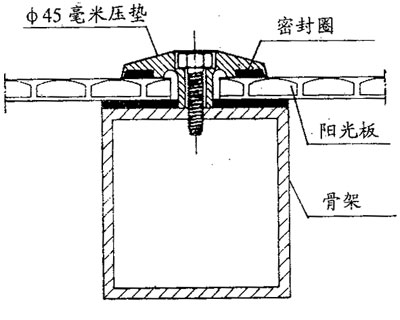

(6) In order to reduce the direct pressure of the material, the gasket can be used to fill the cushion, but the PVC gasket and some rubber ring will destroy the PC board and can not be used. It is recommended that the gasket be made of three yuan ethylene propylene rubber, silicone rubber and neoprene.

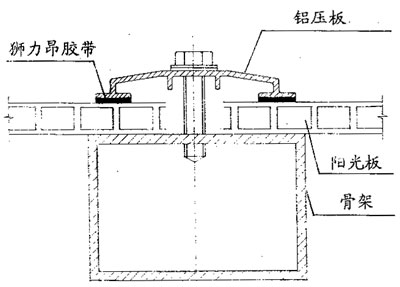

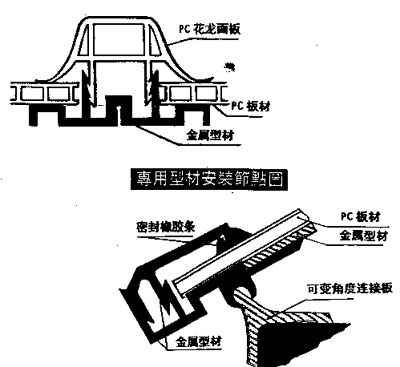

Dry assembly method

Dry, that is, do not use sealant. Because sometimes it occurs that the amount of expansion of the sheet exceeds the elongation of the sealant

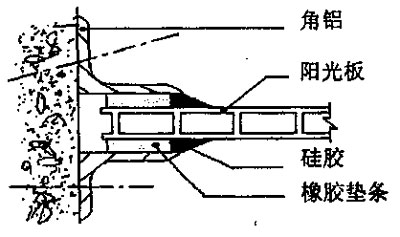

For the sake of aesthetics, the advantage of the dry assembly system is that the sealant is pressed in the inside of the bar (aluminum alloy profile) so that the plate can move freely when it is inflated and loaded.

Warning!

The PVC sealant shall not be used, because the plasticizer added in soft PVC migrates to the surface of the board, which will cause the surface crack of the board and even destroy the whole board. The applicable sealing strip materials are neoprene, or EPDM, etc., and their hardness is about Shao A65.

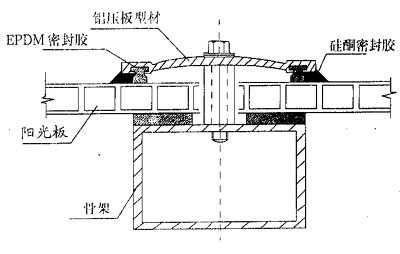

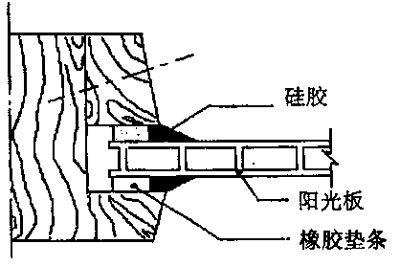

Wet assembly method

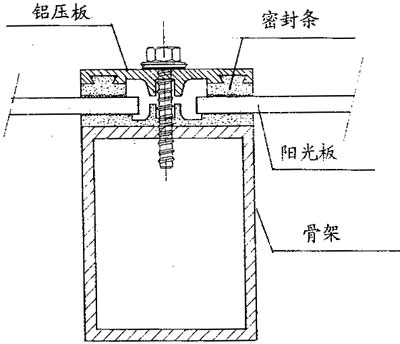

The assembly system is mainly used in small facilities such as garage, station awning, rain canopy, greenhouse, and many other glass substitutes. When the wet assembly method is used, as shown in Figure 2, the basic requirement is that the sealing system shall be able to withstand a certain amount of movement of the plate and allow thermal expansion without reducing its bond with the frame and plate. The General Assembly recommended the use of wet neutral silicone sealant and hollow sunshine board, but should pay special attention to in the use of chemical sealant must check with absolutely can not use alkaline and acid curing agent of silicone rubber, because these will lead to plate cracking, especially when the internal stress, in the selection of sealant, in addition to considering the chemical adaptability, but also the focus of inspection, elongation and weather resistance.

Firm edge condition

Whether dry assembly or wet assembly, horizontal, vertical and oblique mounting. In the hollow sunshine board installation project, the most important thing is the fastening of the edge, we must pay attention to the following two points:

(1) in the connecting section or in the inlaid groove of the frame, there must be some space to allow the plate to be expanded and loaded. The linear thermal expansion coefficient of the hollow sunshine board is 7 * 10m/m.k, namely increasing the temperature of 1 DEG C, 1m * 1m plate along the length direction of the expansion of the 0.075mm, the user must according to the location of the project is divided into four seasons temperature, calculate the installation clearance data: such as the northern region, the highest temperature is 40 DEG C, the temperature of -30 DEG C. Plate 1m * 1m installation clearance is 0.07 * 70=4.9mm

(2) at least one arrow rib shall be included in the clamped portion of the plate or at least 20mm of the part to be engaged at the edge of the plate.

In general, the overall depth of the slot formed by the profile shall include the engagement of the 20mm, plus the clearance required for thermal expansion and deformation due to the load.

- Requirements for cold bending of PC boar…2017-03-14

- Sealing technology of PC board2017-03-14

- PC board installation precautions2017-03-14

- Storage and transportation of PC plates2017-03-14

- PC plate material properties2017-03-14